Automotive Ethernet: The Future of In-Vehicle Networking

In-vehicle networking is evolving at a rapid pace as a result of development in autonomous driving and connectivity that drive the automotive industry forward. More features need to be supported to enhance efficiency, safety, and of course – the driving experience. As a result, requirements on data bandwidth and the number of cables; as well as factors such as complexity, flexibility, and cost effectiveness become more challenging.

To enable autonomous driving, a combination of technologies must be well-integrated onboard the car. This includes long-range radar, short/medium range radar, LIDAR, cameras, ultrasound sensors, and GPS, all operating at different data rates and communication protocol. As a result, these decentralized networks are increasingly evolving into centralized network architectures.

Automotive Ethernet is emerging as a preferred choice for future in-vehicle networking. So, what is it and how will it impact the current network architecture?

Why Automotive Ethernet?

Automotive Ethernet is the new physical layer standard, using the Ethernet standard as an in-vehicle network technology. It offers high immunity, reduced cabling and high-speed data rates. High immunity and reduced cabling are the two big innovations that helped bring Ethernet inside the vehicle. Without the high immunity capability, the standard Ethernet that we are familiar with, 100Base-T and 100Base-TX wouldn't be able to withstand the harsh electromagnetic environment inside the vehicle.

Figure 1 shows a high-level overview of the physical (PHY) layer. As you can see, the Standard Ethernet 100Base-Tx is a dual simplex configuration with 2 twisted pairs. In comparison, the Automotive Ethernet 100Base-T1 is a full duplex link with a single twisted pair that can transmit 100 megabits per second (Mbps) in each direction. That means an aggregate of 200 Mbps communication is theoretically possible between nodes. The same improvement can be seen on the 1000Base-T1.

There is a huge difference when you compare Ethernet speeds with those of CAN, CAN-FD, LIN and FlexRay that run at bits per second or kilobits per second speed. This clearly shows the advantage of automotive Ethernet which can cater to the greater demand for bandwidth in autonomous vehicles (AV).

Networking Architecture Design Change

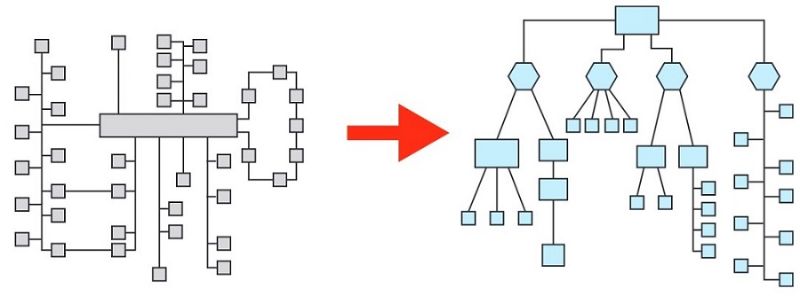

Now, let’s look at how the development of the network architecture is being impacted by automotive Ethernet. The left diagram in Figure 2 shows the heterogeneous networks. The right side of the networks could be a MOST network in its ring topology. The left side of the networks could be a CAN or CAN-FD bus where multiple nodes can access the bus directly. This is consider a classic topology where there is only a single level of communication. All of the communication between the sub-networks can be managed directly by the central gateway. On the other hand, the right diagram of Figure 2 is the hierarchical homogenous networks, with classic technologies like CAN, CAN-FD, LIN, and FlexRay at the lowest layer. The second layer of the network (depicted by the hexagons), are the intermediate gateways between Ethernet and the classic technologies. The rectangle on the top layer can be a switch or a unit with only Ethernet ports. This is to enable the communication to all the networks in a more responsive way.

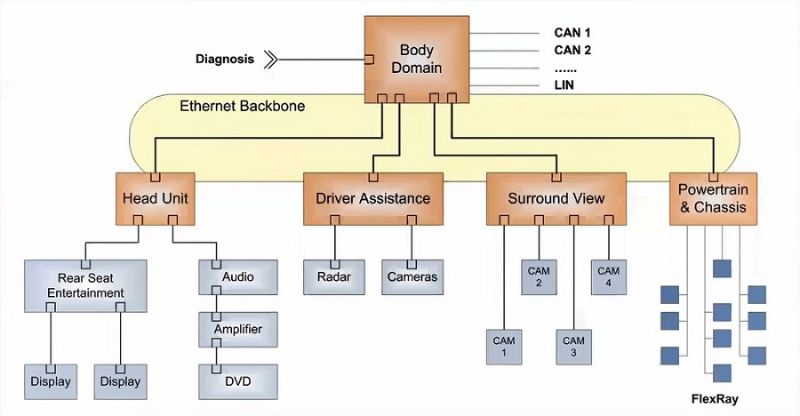

Figure 3 illustrates the application of hierarchical homogenous networks. We have the head unit, driver assistance, surround view, and powertrain & chassis, with inter domain gateways translating the classic technology to the Ethernet. These translations between different technologies, also known as the Ethernet backbone, allows the sub units with its intermediate gateways to connect to the Ethernet enabled central gateway. The vision of enabling automotive Ethernet at one gigabit per second is already a reality, with many OEMs using this architecture as their Ethernet backbone.

Evolving Automotive Network Architecture

Network architecture will need to become model-specific, as both low- and high-end vehicles have different needs. Automotive Ethernet will not replace all networking needs at the moment, but will coexist with classic bus networks for a long time to come. This is because cost is a key hindrance preventing wider adoption of automotive Ethernet. Classic technologies like CAN, CAN-FD, and LIN are well established and cost-effective. They will remain relevant for specific fields of application, especially those where low cost and low bandwidth are key design specifications.

With greater connectivity, cybersecurity will need to become a critical design consideration. In comparison to CAN, automotive Ethernet security is complex and will require expertise and dedicated central management. A more thorough and effective cybersecurity solution needs to be developed in tandem with the network design. I will discuss this topic in my next blog, so stay tuned.

Feel free to drop me an email (mei-ching-maggie.lim@keysight.com) with your comments or questions.

Stay safe and stay healthy!