Accelerating Innovation and Time to Market for 5G Components

5G represents significant revenue potential for the entire mobile ecosystem- chipset and component manufacturers, device makers, network equipment manufacturers (NEMs), and mobile network operators (MNOs). 5G is also an exponential increase in technical complexity. Massive multiple input, multiple output (MIMO) antennas, for example, require multiple transmission and reflection measurements for each antenna element. Component manufacturers need to deploy effective strategies for characterization and test.

5G generates significant multiport challenges

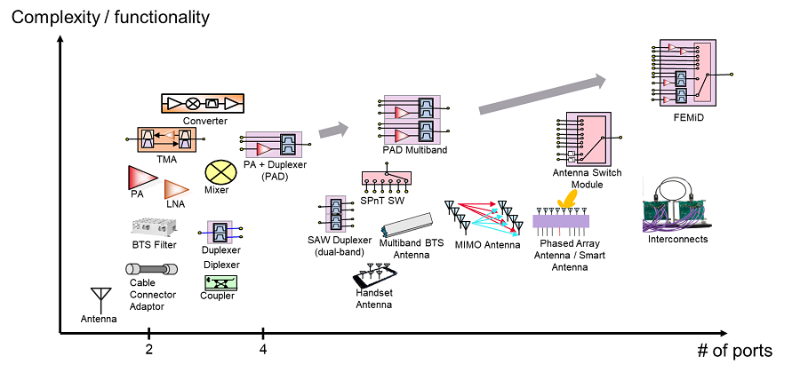

Components feature an increasing number of ports. Multiport characterization is a growing need for components.

Figure 1 shows the increasing number of ports and complexity of various components.

Massive MIMO, in particular, requires massive multiport testing to characterize antenna performance. 5G New Radio (5G NR) frequency range 1 (FR1) requires up to 66 ports. An 8x8 MIMO configuration needs 64 ports for antenna measurements and two ports for calibration.

Maximizing multiport device testing with optimized instrumentation is a critical strategy for component manufacturers to deploy. Instrumentation optimized for multiport measurements ensures comprehensive device-under-test (DUT) support, and helps achieve high measurement performance and accuracy. This helps increase measurement throughput, minimizing the cost of test.

5G requires instrumentation optimized for multiport testing

Switch-based vector network analysis solutions have traditionally addressed multiport testing needs. However, many multiport devices require measurements from each port to every other port. Simple switch test setups cannot address this requirement, because there is no path between the switches that branch from the same port from the vector network analyzer (VNA). Switch-based solutions do not support all the paths for multiport devices.

Component manufacturers can use full crossbar setups in place of simple switch setups. Such setups offer complete measurements between each port. However, they typically require full N-by-N calibration for every case. Also, setups featuring solid-state switches are sensitive to temperature. They require frequent calibration to ensure accurate measurements. More stringent calibration requirements impact throughput.

Modern multiport devices also increase the need for faster and more accurate measurements. As the number of ports increases, the number of sweeps needed to route test signals to each DUT port skyrockets. Switch attenuation impacts the dynamic range, reducing measurement performance.

True multiport VNAs reduce loss because they do not need switches. A VNA optimized for multiport testing also supports all the paths for multiport devices. A wide dynamic range enables them to perform sweeps quickly. An increase of 20 dB in dynamic range can lead to a 100x improvement in measurement speed. With simultaneous data capture, multiple ports are measured concurrently, accelerating the testing process.

Mastering the increasing complexity of components from 5G

Significant competition exists in the 5G space throughout the mobile ecosystem. Component manufacturers need to deploy strategies that accelerate innovation and time to market. In addition, they must overcome the cost-of-test challenge. It will be important for them to augment existing test strategies with new ones. Maximizing multiport testing with optimized instrumentation is critical but there are also other strategies to deploy across the component workflow for a reduced test footprint and higher throughput.

Learn more about multiport testing and other strategies that accelerate the time to market for 5G components in our latest white paper Top 5 Strategies for 5G Component Characterization and Test.